Exploring the Advantages of CNC Milling Manufacturing with Huapin

CNC milling manufacturing has revolutionized the precision machining industry, offering unparalleled efficiency and accuracy in producing high-quality parts. In this article, we will delve into the benefits of CNC milling manufacturing and highlight the services provided by Huapin, a leading brand in the field.

Learning about CNC Milling Processes

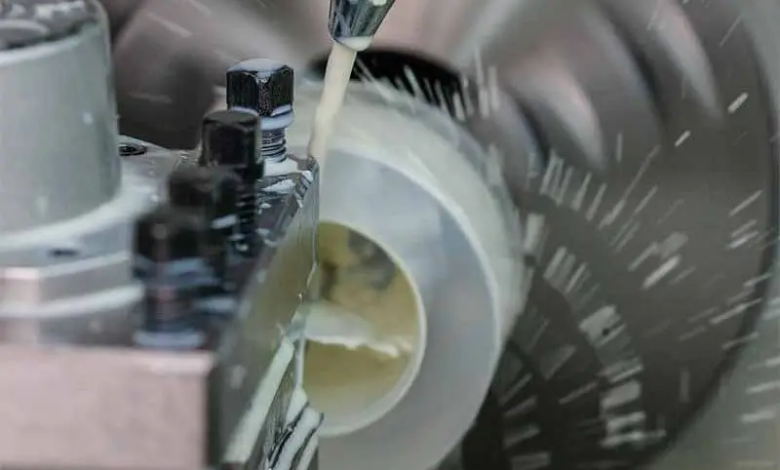

CNC milling is a process that utilizes computer numerical control (CNC) technology to automate the cutting and shaping of materials. It involves removing excess material from a workpiece using rotary cutters, guided by computer-aided design (CAD) software. Huapin specializes in providing CNC milling services for a wide range of materials, including plastics and metals.

Versatility and Precision in Materials

- Plastic Materials: Huapin offers CNC milling manufacturing for an extensive array of plastic materials such as ABS, ABS+PC, PC, PP, PEEK, POM, Acrylic, Teflon, and more. These materials are ideal for various applications, ensuring flexibility and customization options.

- Metal Materials: With expertise in CNC milling, Huapin caters to metal materials like aluminum, brass, copper, magnesium, titanium, stainless steel, tin, zinc, and others. This versatility enables them to address diverse industrial requirements, delivering durable and functional components.

Conclusion

As evidenced by the versatility, precision, and quality of CNC milling manufacturing, Huapin serves as a reliable partner for businesses seeking top-notch machining solutions. Their proficiency in working with an extensive range of materials, both plastic and metal, ensures that customers receive tailor-made components that meet their specific requirements. With Huapin’s expertise and dedication to excellence, clients can trust them to deliver superior CNC milling manufacturing services for various industrial applications.